Inspection And Measurement Of Engine Piston

Inspection and measurement of engine piston:

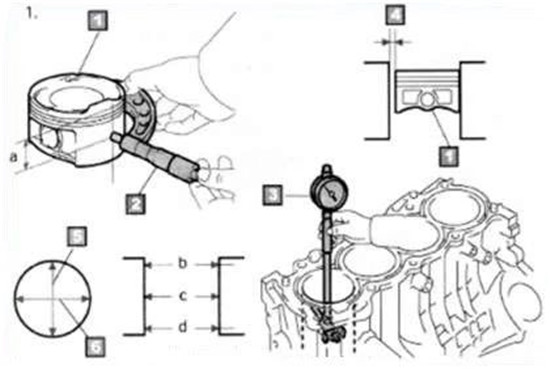

1. Piston appearance inspection

Appearance inspection of piston. The first step is to clean the pistons for reuse, and then check carefully for cracks, piston ring grooves, and piston pin holes.

2. Measurement of piston

Measure the diameter of the piston. Measurements are recommended along specific points in the skirt. Piston diameter can be measured by outside micrometer. Check the piston skirt diameter specification. The specific measured position is related to piston material, structure and temperature. Usually the piston measurement position is the direction perpendicular to the piston pin hole on the thrust surface of the piston, usually at the maximum size of the skirt.

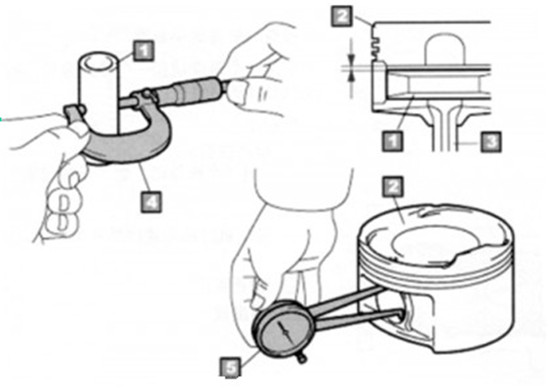

3. Measurement of piston pin

Piston pin inspection items include: piston outside diameter measurement and piston pin hole measurement.

(1) outside diameter measurement of piston pin.

(2) measure the pin hole diameter of each piston.

(3) calculate the clearance between the piston pin and the piston pin hole, and replace the piston or piston pin if necessary.

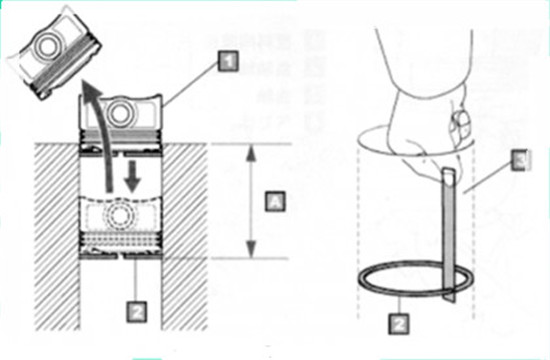

4. Measurement of piston ring opening clearance

Use the unringed piston to head the ring in the cylinder. Measure the opening clearance of the piston ring with a feeler. Compare the measured results with the standard values in the maintenance manual. Excessive clearance will cause excessive gas or excessive oil burning. If the clearance is too small, the piston ring will become stuck or broken in the cylinder after engine heating.

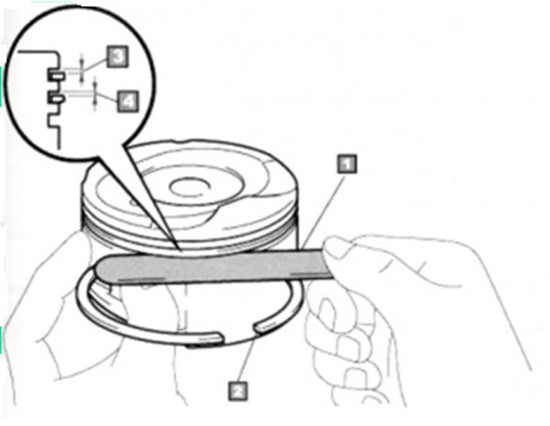

5. Piston ring side gap measurement

A new piston ring is pushed into the cylinder using the piston to keep the ring level and then measured with the plug at the specified position where the piston ring has the least wear. See the technical specification in the repair manual for the correct side gap values. If the side gap is too large, it indicates that the piston ring groove is worn or the thickness of the ring is wrong, so it needs to be replaced.

Mobile:

Mobile: E-mail:

E-mail: